AP&S

Nassprozessanlagen für die Halbleiterindustrie: Wir sind Ihr Partner! NassprozessanlagenKarriere bei AP&SBeREICHE

Hightech & Expertise

Seit über 20 Jahren liefern wir leistungsstarke Nassprozessanlagen für die Oberflächenbehandlung von Wafern an die führenden Halbleiterhersteller weltweit. Unser modulares Produktspektrum ist perfekt auf die Bedürfnisse der Halbleiterbranche zugeschnitten, unabhängig davon, ob eine Standard-Nassprozessanlage oder eine kundenspezifische Lösung benötigt wird.

Anwendungsfelder

Wir bieten eine umfassende Palette an chemischen Nassprozessen für die Wafer-Bearbeitung im Mikrochip-Herstellungsprozess: Reinigung, Trocknung, Ätzung, Resist-Stripping, Entwicklung, Lift-off, stromlose Metallabscheidung für UBM und weitere.

Service

Mit einem ganzheitlichen After-Sales Konzept stellen wir die nachhaltige Kundenunterstützung weltweit sicher. Zuverlässig und kompetent: Ob es um Serviceeinsätze, Ersatzteilbeschaffung, Modernisierung (Refurbishment) oder Nassprozess-Schulungen geht.

Unternehmen

Weitsichtig, kundenorientiert, innovativ und dem stetigen Fortschritt verpflichtet – das ist AP&S und seine Nassprozessanlagen. In der Halbleiterindustrie weltweit zu Hause, gestalten wir die Zukunft der Halbleiterproduktion mit!

Reinigen

Reinigungsprozesse unter Verwendung von Reinchemikalien erfordern adäquate reine Gerätelösungen mit fortschrittlicher Oberflächen- und Strukturwechselwirkung.

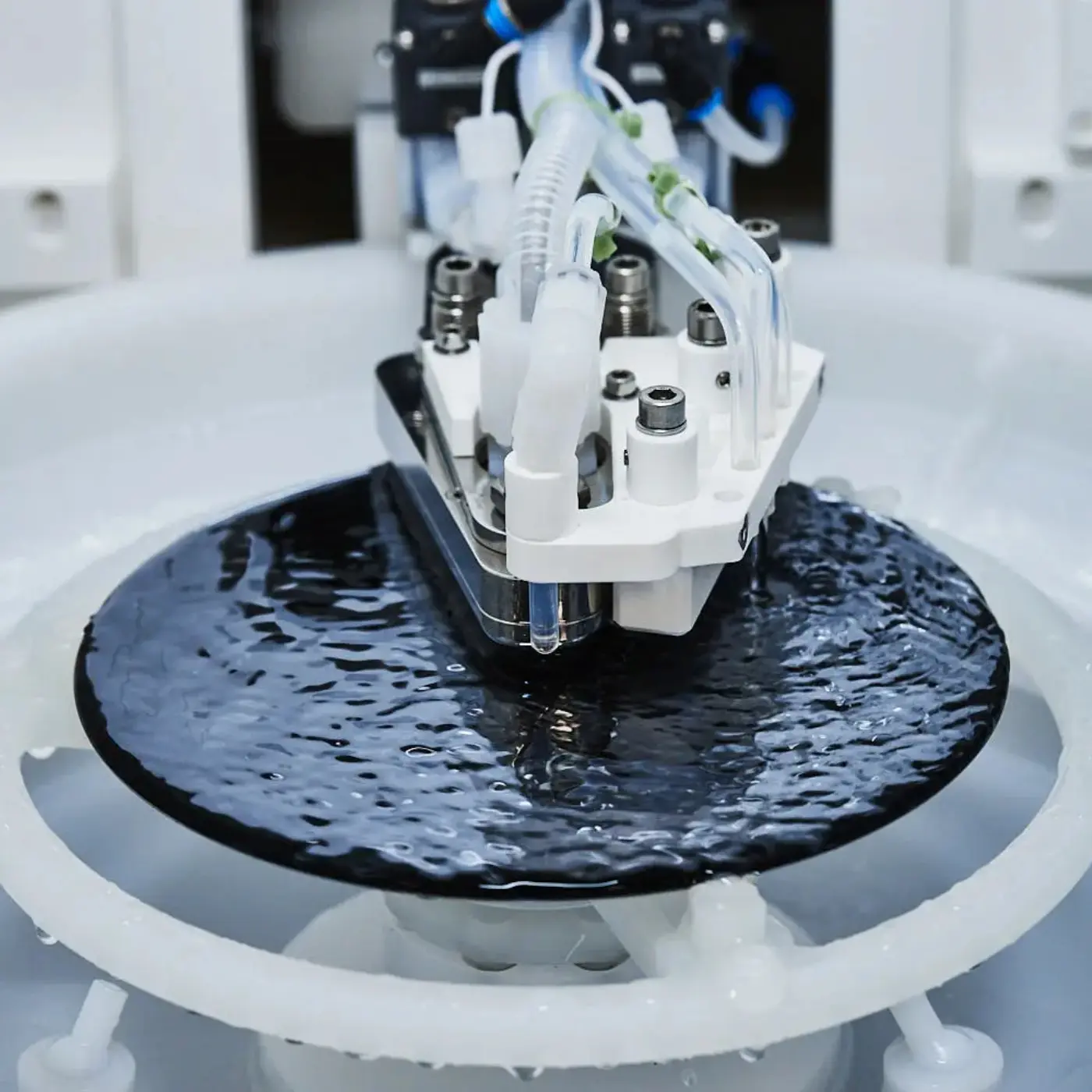

Ätzen

Ätzprozesse der verschiedenen SC-Materialien erfordern eine Hardware, die für die verwendeten hochreinen Ätzchemikalien optimiert ist.

Photoresist (PR) Stripping

Nach dem Ätzen ist die Struktur ein permanenter Teil der oberen Wafer-Schicht. Der Lack, der als Ätzbarriere fungiert hat, wird von der Oberfläche entfernt.

Entwicklung

Die Lackstruktur wird durch die chemische Auflösung des nichtpolymerisierten Lackbereichs entwickelt. Die Entwicklung bildet in der Lackschicht eine Struktur mit den genauen Abmessungen, die im Prozess von Schaltungsentwicklungen festgelegt wurden.

Metallätzen

Metallstruktur-Ätztechnologien für Al, Ti, W und andere: Vollständige Entfernung von Metallen von Geräte- oder Monitor-Wafern für Wafer bis zu einem Durchmesser von 300 mm.

Stromloses Plating

Das Flip-Chip-Bonding ist von zunehmender Bedeutung für die weitere Miniaturisierung von Bauelementen. Die Under-Bump-Metallisierung wird mit stromloser Abscheidungstechnologie auf Al-Legierungs- und Cu-Substraten durchgeführt.

Wafer-Trocknung

Marangoni-Trocknung: Die Oberflächenspannung des Wassers besitzt eine einzigartige Beschaffenheit, wenn Wafer langsam durch eine Wasseroberfläche gezogen werden: Die Spannung zieht das Wasser von der Oberfläche weg und lässt die Wafer trocken.

Lift-off-Verfahren

Metal-Lift-Off ist ein Strukturierungsprozess, der die Ätzvariationskomponente eliminiert. Die Wafer werden in einem Entwicklungsschritt verarbeitet, wobei ein Loch in der Lackschicht verbleibt, in dem sich die abgeschiedene Schicht über dem Lack und in der Öffnung befindet.

Team

Teamplayer

Der Zusammenhalt unserer Belegschaft ist die treibende Kraft für unseren Erfolg. Es ist die Individualität unserer Kolleg:innen, die wie Puzzleteile ineinandergreifen und die modernen und dynamischen Arbeitsstrukturen unseres Unternehmens entstehen lassen.