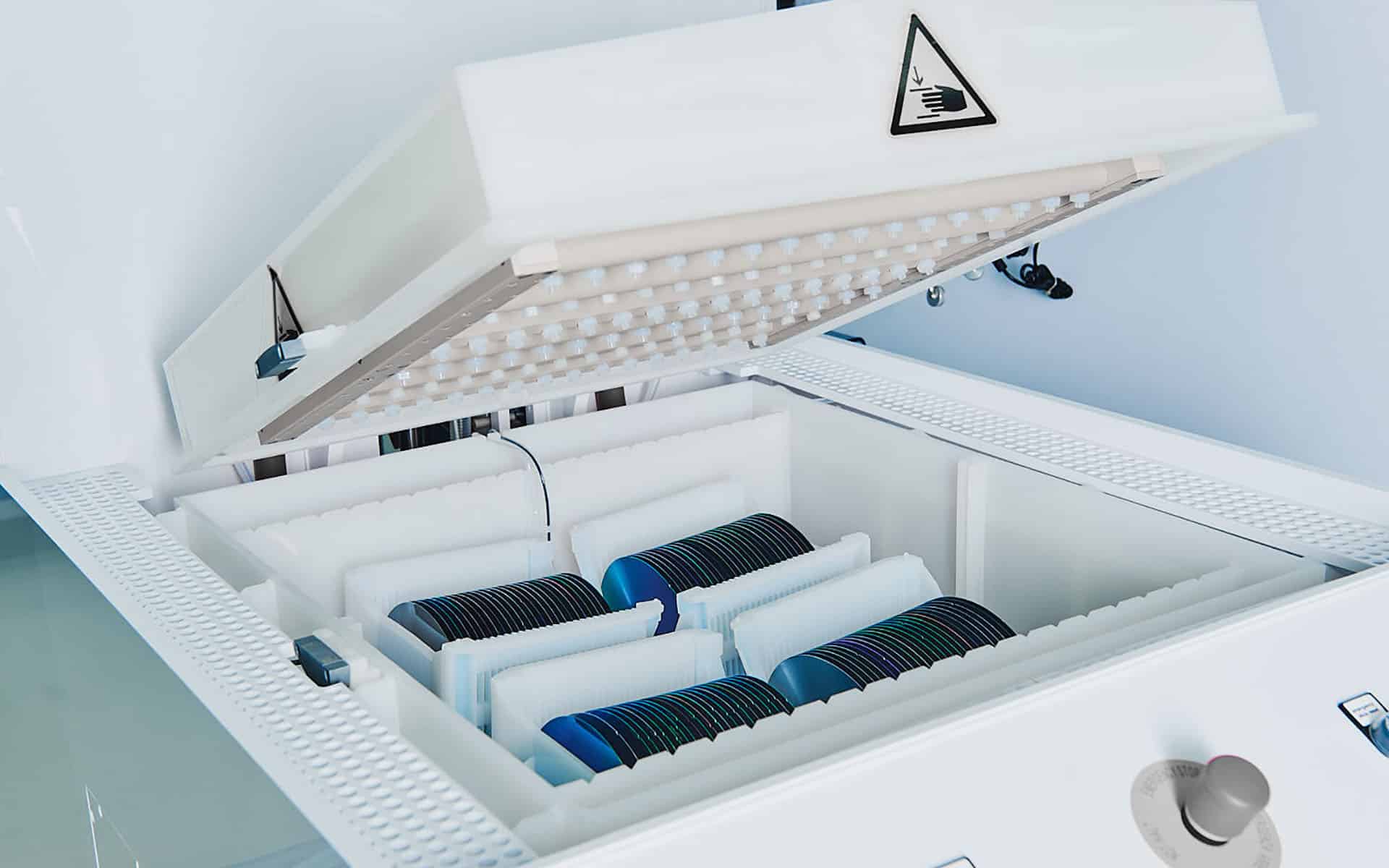

NID Dryer

Efficient drying plant for IPA drying in combination with N2

NID Dryer

AP&S PRODUCTS

The All-Rounder

The NID dryer provides fast, uniform and energy-efficient drying of wafers in semiconductor production.

Main Benefits

- One dryer for different substrates up to 300 mm: 25 or 50 wafer batches

- Wafer thickness from 120 to 2000 µm without modification

- Available as a stand-alone unit or integrated into a wet process bench

- Average process time 10-12 minutes

Processes

Drying processes with IPA and N2

Substrates

- Substrates

Wafers, MEMS, optoelectronics, photomasks, glass - Wafer material

Si, SiC, GaN, GaAs, sapphire, glass - Wafer sizes

up to 12″

Technical Features

- For cassettes with high or low profile

- Low IPA consumption: ≤ 30 ml / run

- Ideally suited for thin wafers

- Complies with: CE, SemiS2 and S8, FM 4910, SECS / GEM

- Proven Reliability:

MTBF ≥ 800 h

Operating time ≥ 97 %