Products

Efficient wet process solutions for your semiconductor production. Whether you need a standard system or a customized wet process solution: Our modular product range is perfectly tailored to your needs!

SOLUTIONS

Products for Wet Processes

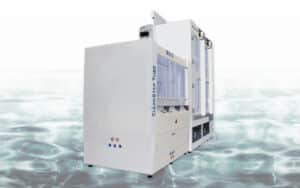

AP&S offers the complete range of wet process equipment from single wafer systems to wet benches for batch processes as well as fab logistics equipment.

From A to Z

The AP&S product range includes manual, semi-automatic and fully automatic wet process solutions for the semiconductor, MEMS and microstructuring industries as well as for the R&D sector. Among others, AP&S equipment covers the following wet processes: cleaning, etching, metal etching, PR stripping, electroless metal deposition, lift-off process, drying, developing and others.

FEOL & BEOL

We offer wet process equipment for batch processes as well as for single wafer processing and equipment for ensuring cleanliness and maximum productivity in semiconductor production such as FOUP, SMIF and box cleaners as well as various chemical management systems. AP&S equipment is used in front-end-of-line (FEOL) and back-end-of-line (BEOL) processes.

Up to 300 mm wafers

AP&S wet process solutions handle masks and wafers up to 300mm in diameter, including various wafer materials - such as silicon (Si), silicon carbide (SiC), gallium nitride (GaN), gallium arsenide (GaAs), sapphire, glass - and different substrate thicknesses.

BATCH

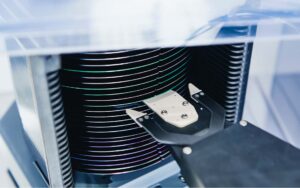

Batch Processes

High throughput, optimized process operating costs, comprehensive process control and consistent process results for vertical wafer processing.

The main feature of batch processes for the production of semiconductor devices and microelectromechanical systems (MEMS) is the simultaneous processing of multiple wafers on the front and back side. AP&S' batch wet process portfolio includes simple manual wet benches for laboratory or R&D purposes as well as fully automated high-end technology wet benches for mass production. Bridge tools for flexible wafer sizes are our strength!

Due to the perfectly coordinated interaction of product design, automation and the required chemicals, our wet process solutions for batch processing offer maximum process reliability, optimized process times, cost efficiency and maximum flexibility.

AP&S's wet benches enable cleaning, drying, etching, PR stripping and electroless deposition (e-less plating) for wafer processing up to 12 inches and masks of various sizes.

SINGLE WAFER

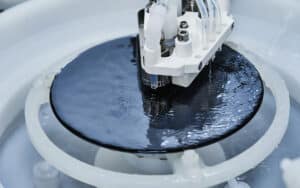

Single Wafer Processes

High-precision processes with high uniformity, high repeatability and extremely precise process control for horizontal wafer processing

AP&S' single wafer processing portfolio includes a variety of processes for the semiconductor and MEMS production chain: cleaning, drying, etching, metal etching, photoresist (PR) stripping and metal lift-off processes.

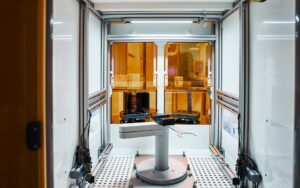

The in-house AP&S laboratory "DemoCenter" offers you a wide range of demonstrations with the single wafer tool.

Our horizontal wafer handling machines can handle all standard substrate formats: 100 mm, 125 mm, 150 mm, 200 mm and 300 mm. Thereby, we cover all common substrate materials and substrate thicknesses in semiconductor production.

Our primary goal is to ensure efficient wet processes in our customers' semiconductor fabs. Therefore, our product range also includes fab logistics equipment such as FOUP and box cleaners, drying units for wafers, cleaning systems for quartz tubes, liners and boats, and chemical management systems.

In this way, our customers receive everything from a single source and have a competent partner at their side for all relevant issues relating to wet-chemical processes in their semiconductor production.

CONTACT

Our Sales Team

"We look forward to connecting with you!"

Hatice Okan

Internal Sales

+49 1761 8983-116