ACADEMY

AP&S Academy

Challenges such as rapid capacity expansion and a shortage of skilled workers affect the semiconductor industry. This is precisely where the AP&S Academy concept comes in, to provide customers with optimum support in mastering these and other tasks in semiconductor manufacturing. We offer individual training formats and training modules covering all aspects of wet process technology. The trainers of the AP&S Academy make your team fit for handling wet process equipment in your semiconductor production, thus ensuring high machine availability and productivity.

MAINTENANCE

Quick & Qualified

Before, during and after commissioning of the AP&S wet process equipment in your semiconductor manufacturing facility, our team of highly qualified field service engineers will provide you with fast and competent support to ensure process reliability, high equipment availability and optimum throughput. This includes competent and qualified maintenance and technical support worldwide, equipment installations, relocations and upgrades on site.

CONTACT SERVICE

Our Team Service

We are there for you. Here you will find your contact person.

Antonino Privitera

Service Italy

+39 333 1156778

E-mail

Swee-Nam Tang

Service Asia-Pacific

+60 440 39007

E-mail

CONTACT AFTER-SALES

Our Team After-Sales

We are there for you. Here you will find your contact person.

Svetlana Altergott

After-Sales - Spare Parts

+49 771 8983-181

E-mail

Sabrina Leuenberger

After-Sales - Service & Maintenance Contracts

+49 771 8983-263

E-mail

Daniel Schnekenburger

After-Sales - Customer Service

+49 771 8983-223

E-mail

Natalie Streidenberger

After-Sales

+49 771 8983-178

E-mail

Petra Vosseler

After-Sales - Repairs

+49 771 8983-179

E-mail

SPARE PARTS

Reliable Delivery for High Machine Availability

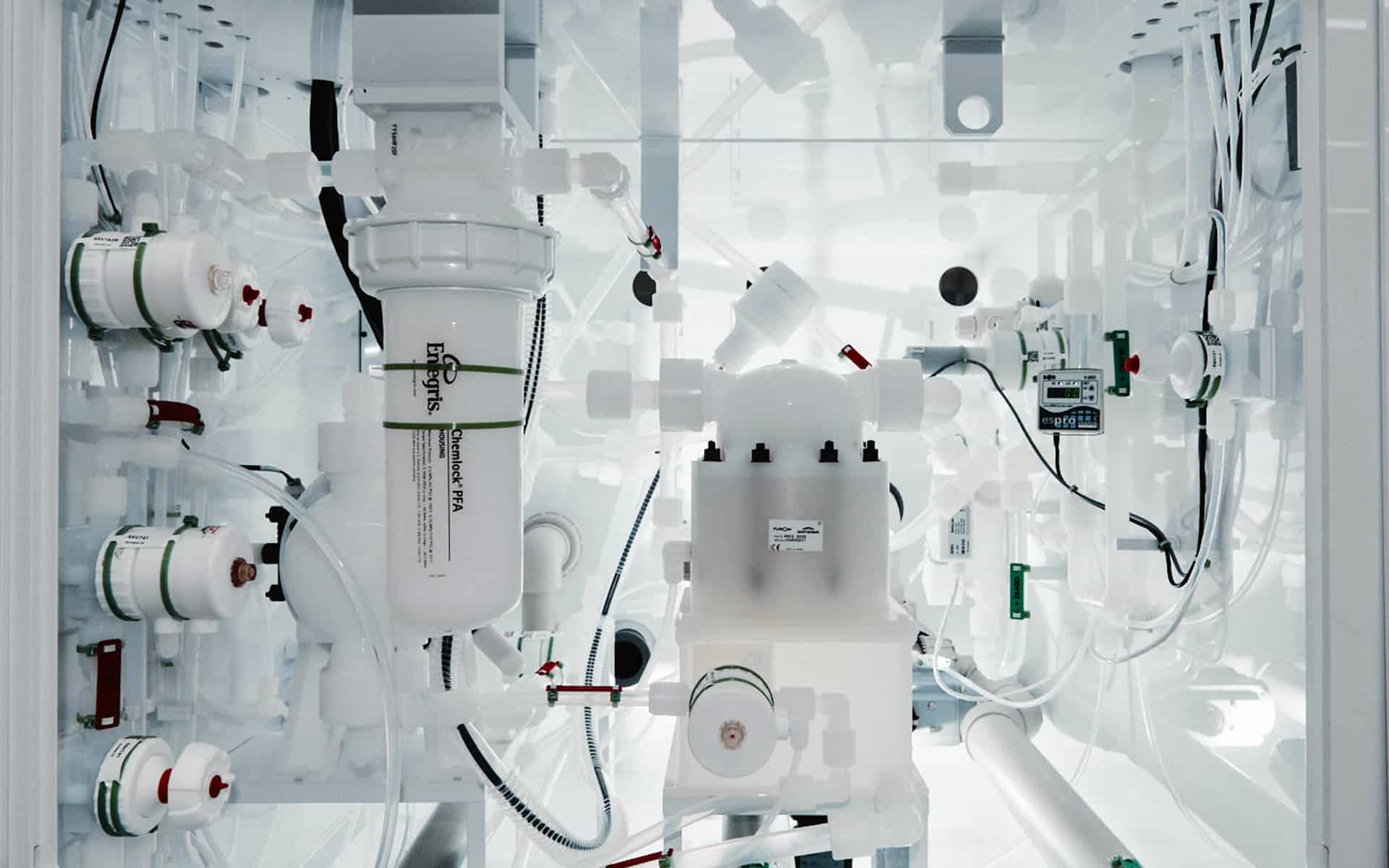

Guaranteed spare parts availability ensures maximum machine availability (uptime) and therefore the efficiency of your wet processing systems. We offer you a wide range of spare parts and the fastest possible delivery worldwide. Delivery is made from our warehouse or from a consignment warehouse on site - both are possible.

MODERNIZATION

Fit for the Future

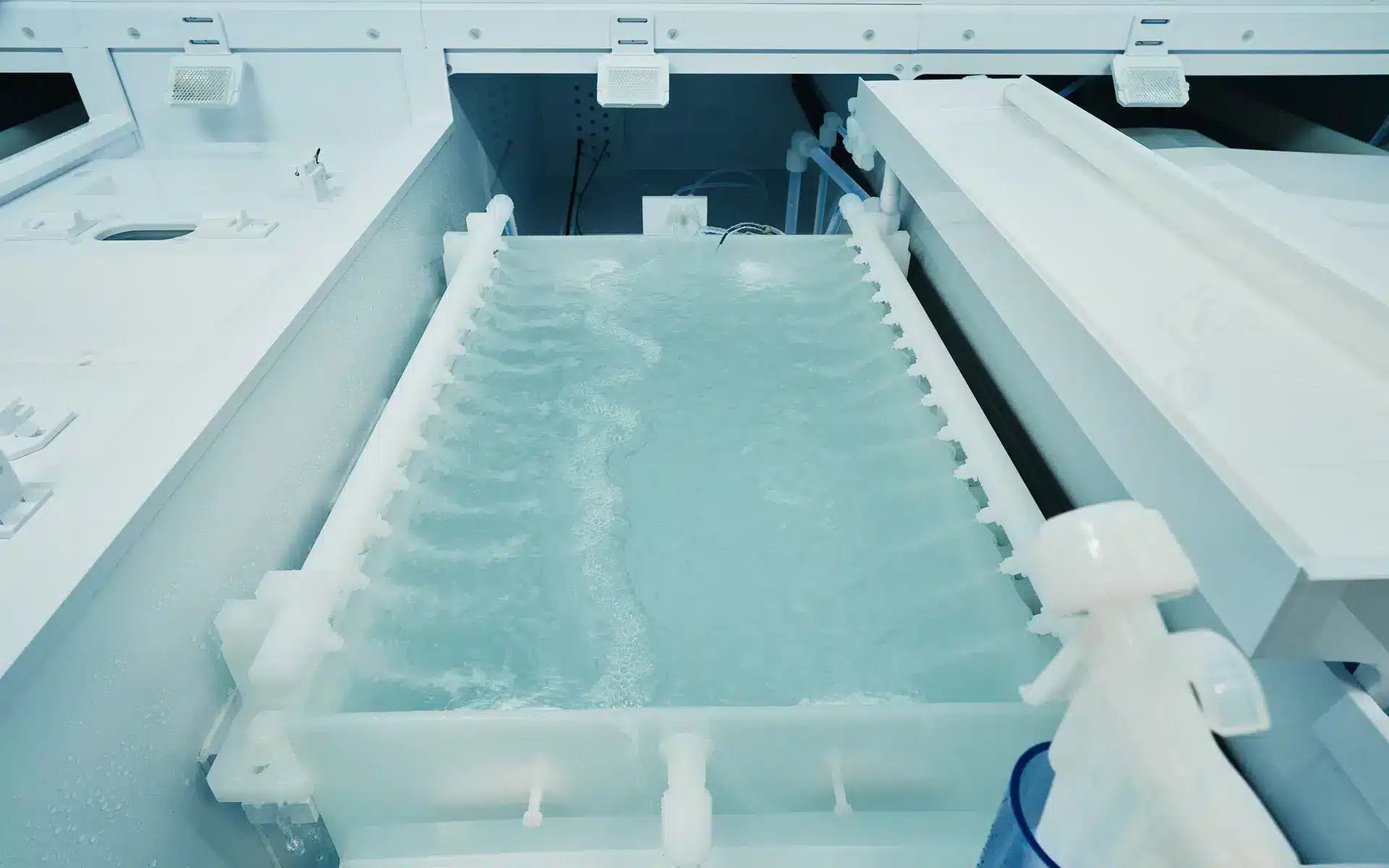

AP&S refurbishment programs bring used and obsolete wet process equipment up to the current state of the art and prepare it for future semiconductor manufacturing requirements. In doing so, we draw on our many years of experience in the field of automation and process control. The focus is always on the specific needs of the customer.

Our refurbishment programs include:

- Overhaul of wet processing machines

- Modifications of process modules

- Integration of SECS/GEM interface

- Integration of new PLC and IPC control standards

- Upgrades for dryers

- Replacement of obsolete components

- Implementation of new tool software

- Adaptation to new standards

- Security upgrades

- Upgrading the level of automation