AP&S

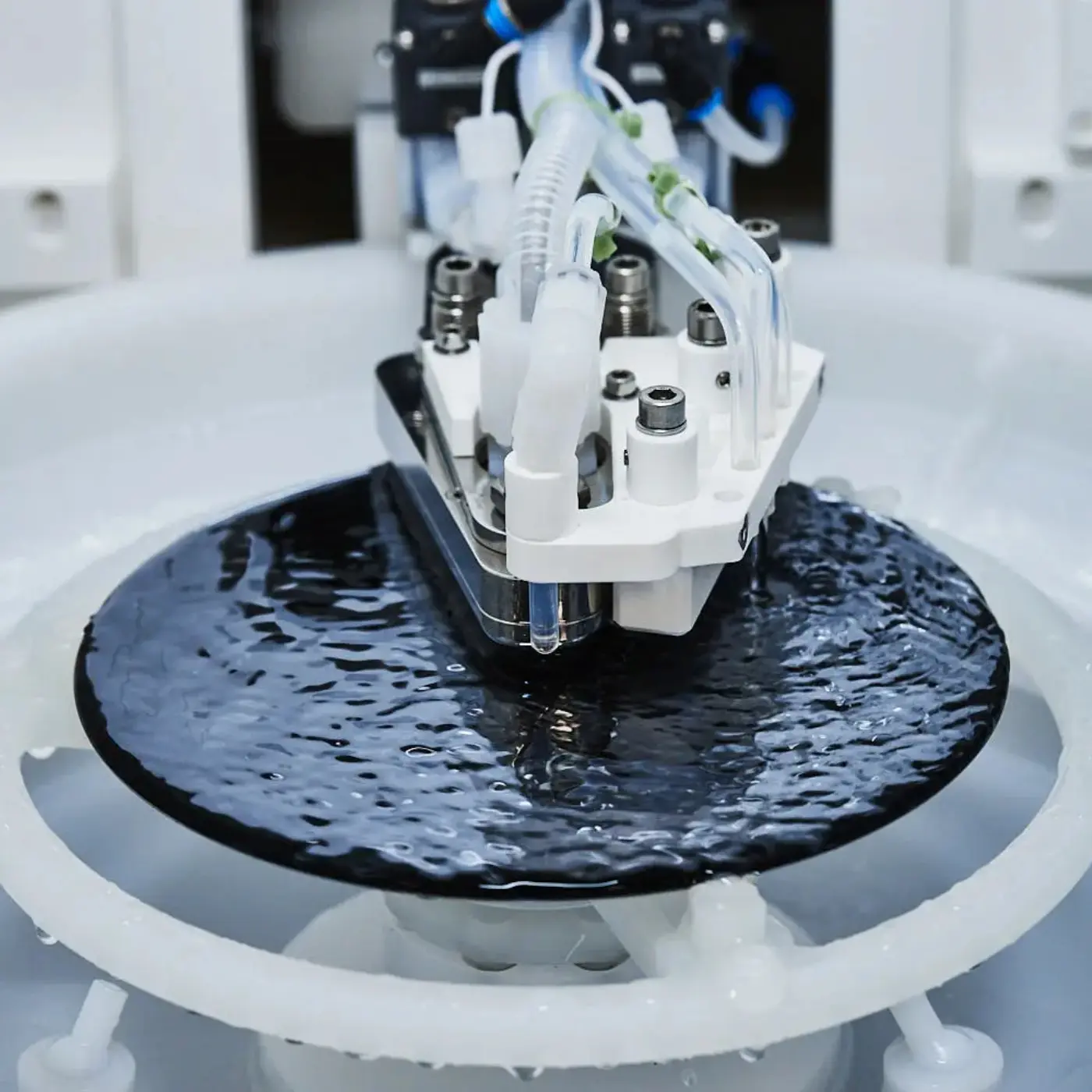

Wet Process Equipment for the Semiconductor Industry: We are Your Partner! Wet Process EquipmentCareer at AP&SAREAS

High-Tech & Expertise

For over 20 years, we have been supplying high-performance wet process equipment for the surface treatment of wafers to the world's leading semiconductor manufacturers. Our modular product range is perfectly tailored to the needs of the semiconductor industry, whether standard wet process equipment or a customized solution is required.

Fields of Application

We offer a comprehensive range of chemical wet processes for wafer processing in the microchip manufacturing process: cleaning, drying, etching, resist stripping, development, lift-off, electroless metal deposition for UBM and more.

Service

With a holistic after-sales concept, we ensure sustainable customer support worldwide. Reliable and competent, whether it is about service calls, spare parts procurement, modernization (refurbishment) or wet process training.

Company

Far-sighted, customer-oriented, innovative and committed to continuous progress - this is AP&S and its wet process equipment. At home in the semiconductor industry worldwide, we help shape the future of semiconductor production!

Cleaning

Cleaning processes using pure chemicals require adequate pure equipment solutions with advanced surface and structural interaction.

Etching

Etching processes of the various SC materials require hardware that is optimized for the high-purity etching chemicals used.

Photoresist (PR) Stripping

After etching, the structure is a permanent part of the top wafer layer. The varnish that acted as an etch barrier is removed from the surface.

Development

The resist structure is developed by the chemical dissolution of the non-polymerized resist area. The development forms a structure in the lacquer layer with the exact dimensions determined in the process of circuit developments.

Metal Etching

Metal structure etching technologies for Al, Ti, W and others: Complete removal of metals from device or monitor wafers for wafers up to 300 mm in diameter.

Currentless Plating

Flip-chip bonding is of increasing importance for the further miniaturization of devices. Under-bump metallization is performed with electroless deposition technology on Al alloy and Cu substrates.

Wafer Drying

Marangoni drying: The surface tension of water has a unique nature when wafers are slowly pulled through a water surface: The tension pulls the water away from the surface, leaving the wafers dry.

Lift-off Procedure

Metal lift-off is a structuring process that eliminates the etch variation component. The wafers are processed in one development step, leaving a hole in the resist layer, in which the deposited layer is located above the coating and in the opening.

Team

Team Player

The cohesion of our workforce is the driving force behind our success. It is the individuality of our colleagues that interlock like puzzle pieces and give rise to the modern and dynamic work structures of our company.