SpinScrubber

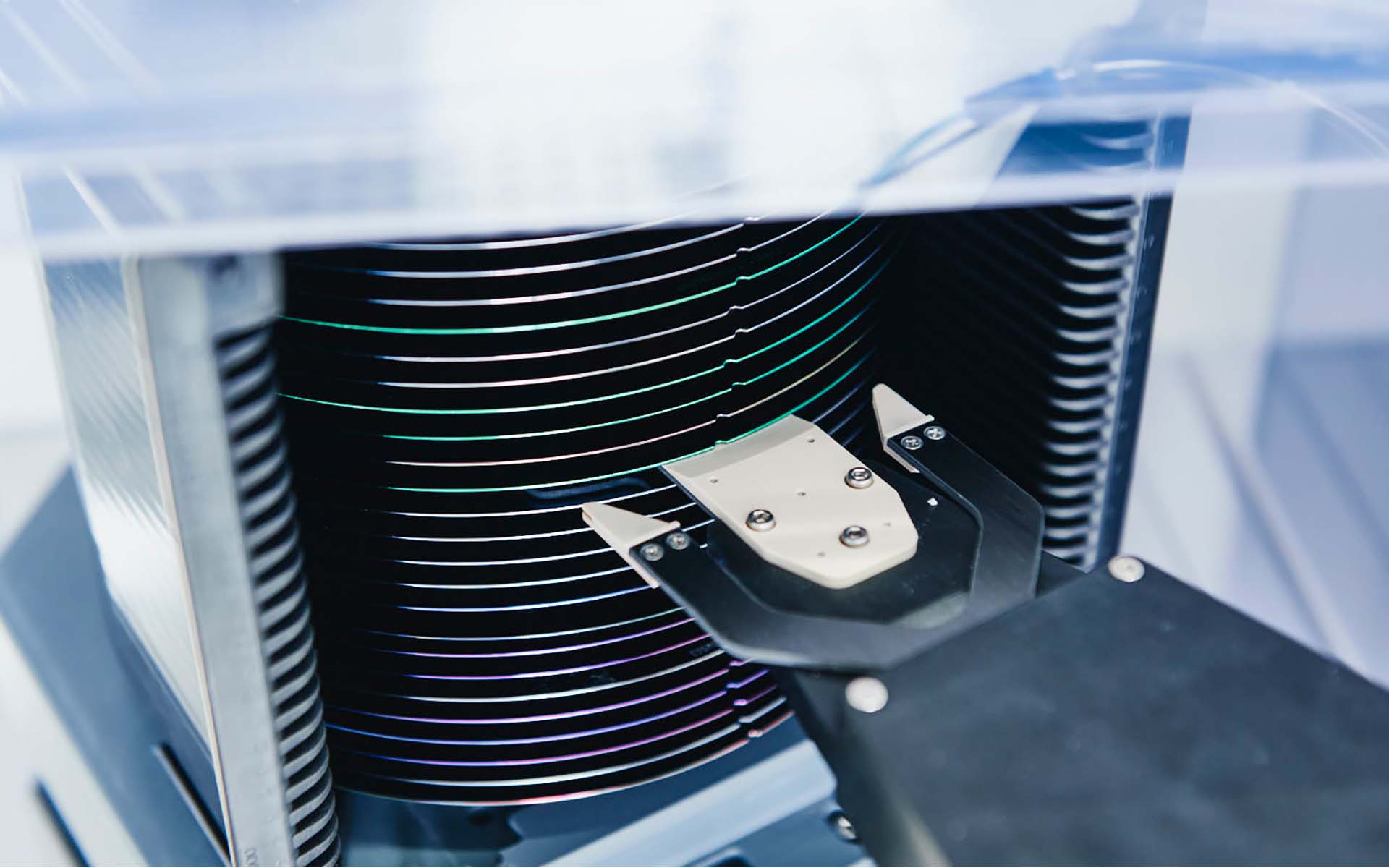

Wet-chemical single wafer process system for efficient particle removal on the surfaces of wafers, MEMS and photomasks

SpinScrubber

AP&S PRODUCTS

Efficient Particle Removal

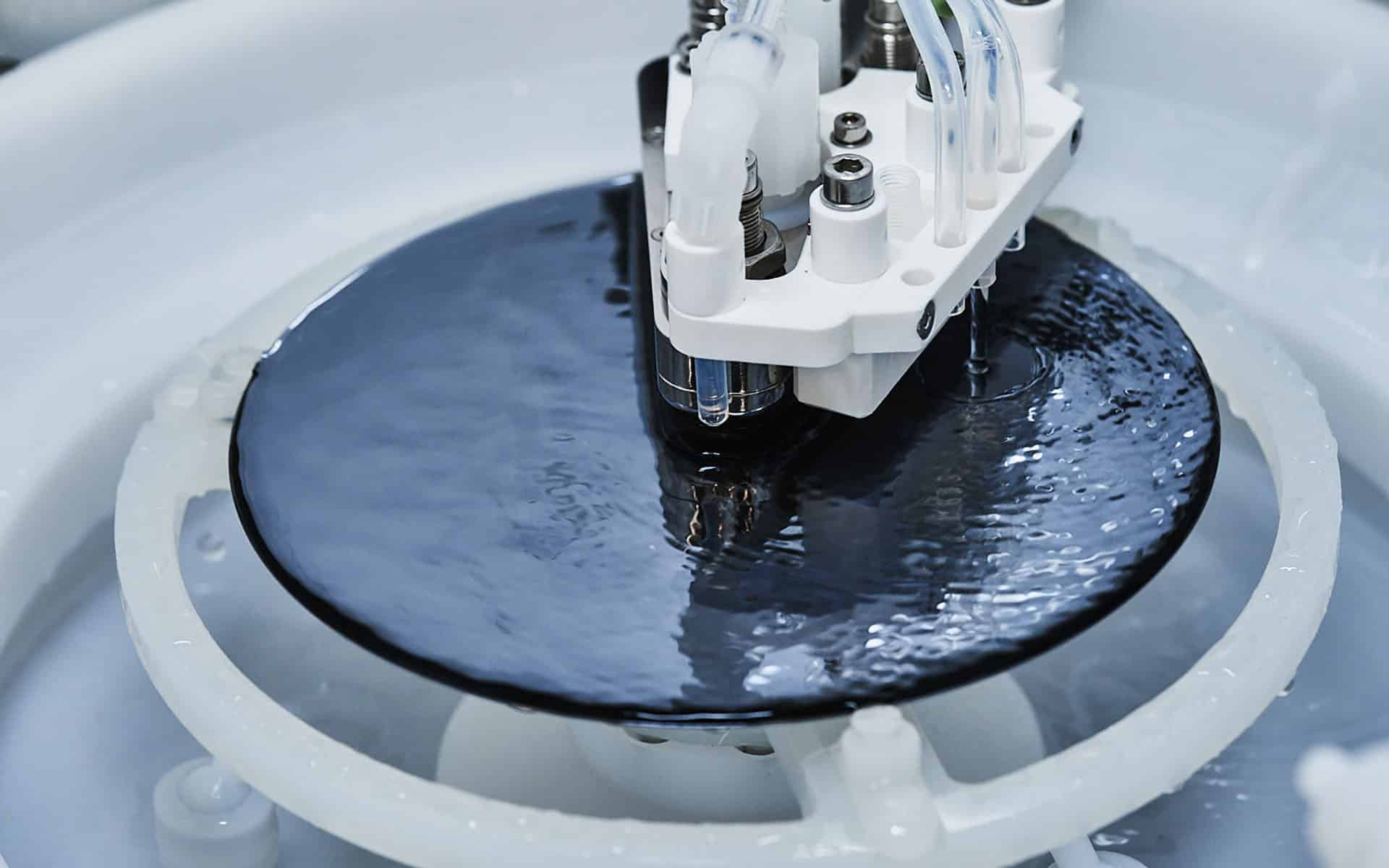

The SpinScrubber single wafer system provides post grind, post polish, bevel clean and other chemical wet processes for substrate surfaces in semiconductor manufacturing.

Main Benefits

- Optimized CoC through low chemical and water consumption: chemical recovery and recycling included

- Parallel cleaning of the front and back side of the wafer is possible.

- Handling of thin wafers

- Up to two different cleaning media in one process tray - A tool demonstration in the AP&S DemoCenter is available.

Processes

- Post grind

- Post polish

- Post CMP

- Backside

- Reclaim

- Bevel clean

- TSV cleaning

Substrates

- Substrates

Wafers, MEMS, optoelectronics, photomasks, up to 9" and square substrates - Wafer material

Si, SiC, GaN, GaAs, sapphire, glass - Wafer sizes

up to 12″

Technical Features

- Easy configuration and flexible upgrading due to modular design

- Maximum safety for workers, plant and environment according to highest safety standards

- Optimized plant footprint, easy feed

- No expensive space for the Chemicals Management System in the clean room is required as it can be placed outside.

- Customized cleaning media on request