SpinEtcher

Proven system for wet processes with end-point detection for FEOL and BEOL processes

SpinEtcher

AP&S PRODUCTS

Endpoint Detection

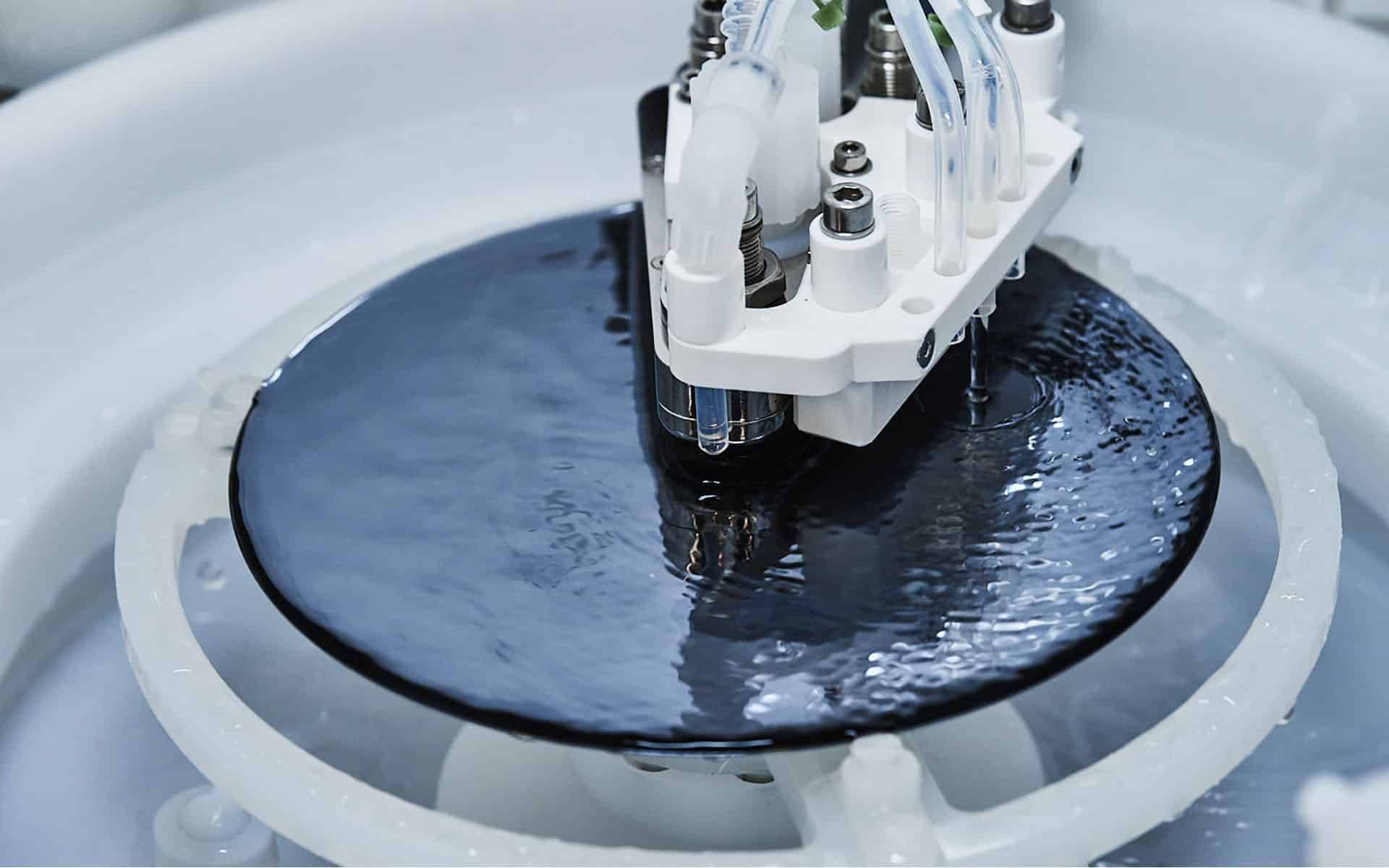

This single wafer wet process system for wafer surface treatment and wafer thinning offers optimum results in FEOL and BEOL etching and cleaning.

Main Benefits

- Optimized CoC due to low chemical and water consumption

- Process safety according to highest safety level for chemicals

- Endpoint detection for highest reliability and process control:

1. Less over-processing time required to fully etch the layer (i.e. over-etching)

2. Less impact on other layers

3. Stable uniformity from wafer to wafer

4. Significant reduction of chemical consumption possible - Convenient handling and easy resizing, up to 5 media in one process tray

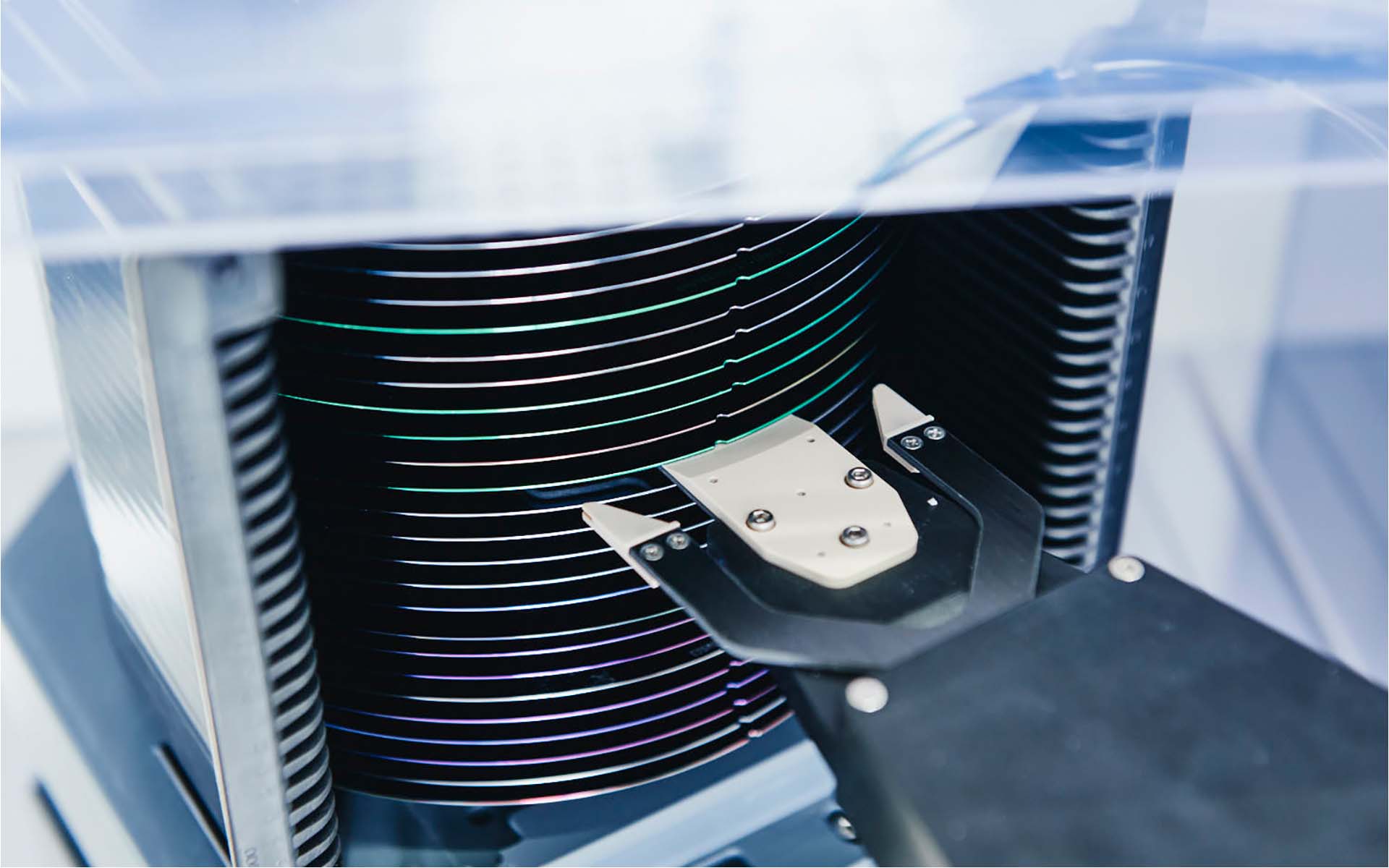

- Handling of thin wafers

- A plant demonstration in the AP&S DemoCenter is available.

Processes

- FEOL etching, BEOL etching and cleaning

- Wafer thinning

- Tension decrease

- Film removal and damage repair

Substrates

- Substrates

Wafers, MEMS, optoelectronics, photomasks, up to 9″ and square substrates - Wafer material

Si, SiC, GaN, GaAs, sapphire, glass - Wafer sizes

up to 12″

Technical Features

- Open cassette, SMIF pod, FOUP

- Easy configuration and flexible upgrading due to modular design

- Maximum safety for workers and plant according to highest safety standards

- Optimized plant footprint, easy feed

- No expensive space for the Chemicals Management System needed in the clean room, as it can be positioned outside