SpinLift-off

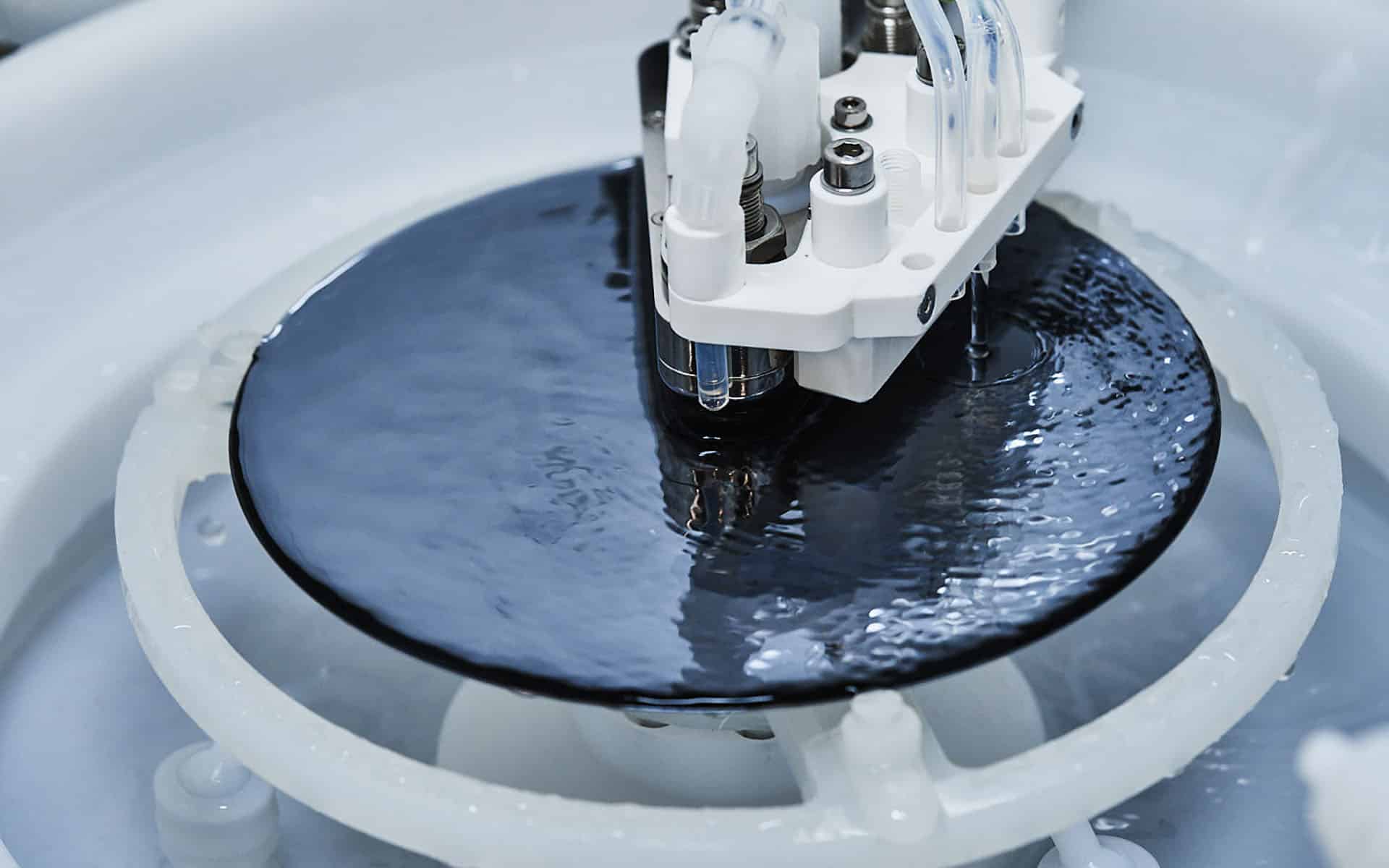

Unique metal lift-off system with DMSO and Megasonic

SpinLift-off

AP&S PRODUCTS

Patented Lift-Off Process

This single wafer wet process system offers a patented lift-off process for unique process performance. Within a few seconds, the metal layer is completely lifted off without affecting the substrate or structures.

Main Benefits

- Unique process performance without affecting substrate and structures

- Use of DMSO (dimethyl sulfoxide), a non-critical EH&S substance (EU & US)

- Complete lifting of the metal layer within < 30 seconds

- Cost-efficient process: recovery of process chemicals and precious metals

- Optimized process time with positive impact on overall throughput

- A plant demonstration in the AP&S DemoCenter is available.

Processes

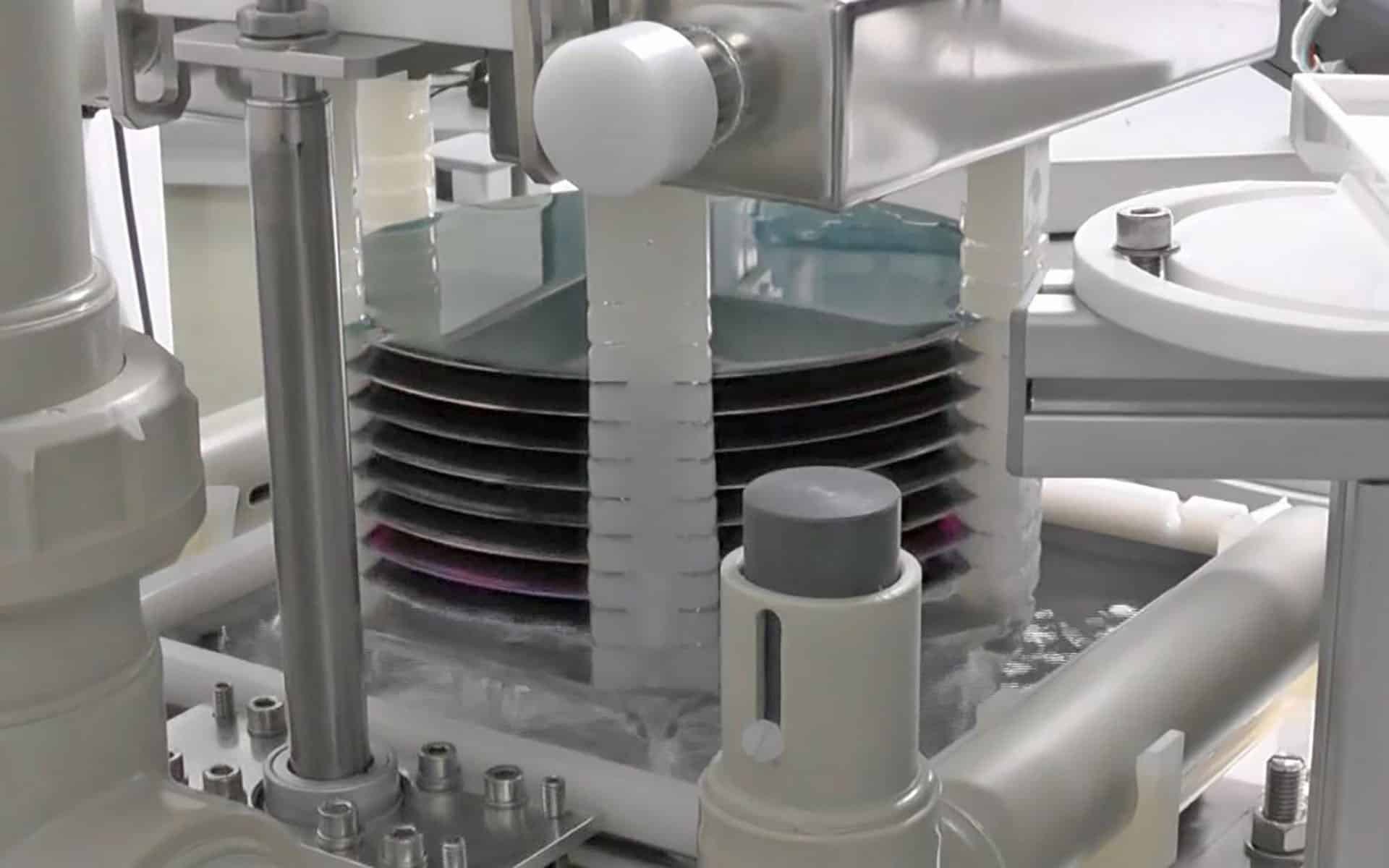

- The AP&S metal lift-off solution is available for all types of metal layers, alloys and other protective coatings used in the semiconductor industry, such as Au, Ag, AlCu, etc.

- Metal lift-off, PR-stripping

Substrates

- Substrates

Wafers, MEMS, optoelectronics, photomasks, up to 9″ and square substrates - Wafer material

Si, SiC, GaN, GaAs, sapphire, glass - Wafer sizes

up to 12″

Technical Features

- High safety for workers, environment and plant

- MegaSonic agitation with field-proven MegaSonic system

- Effective rinsing through optional high-pressure DIW

- Rinsing with solvent (e.g. IPA) is available

- Easy configuration and flexible upgrading due to modular design

- Optimized plant footprint, easy feed