TwinStep

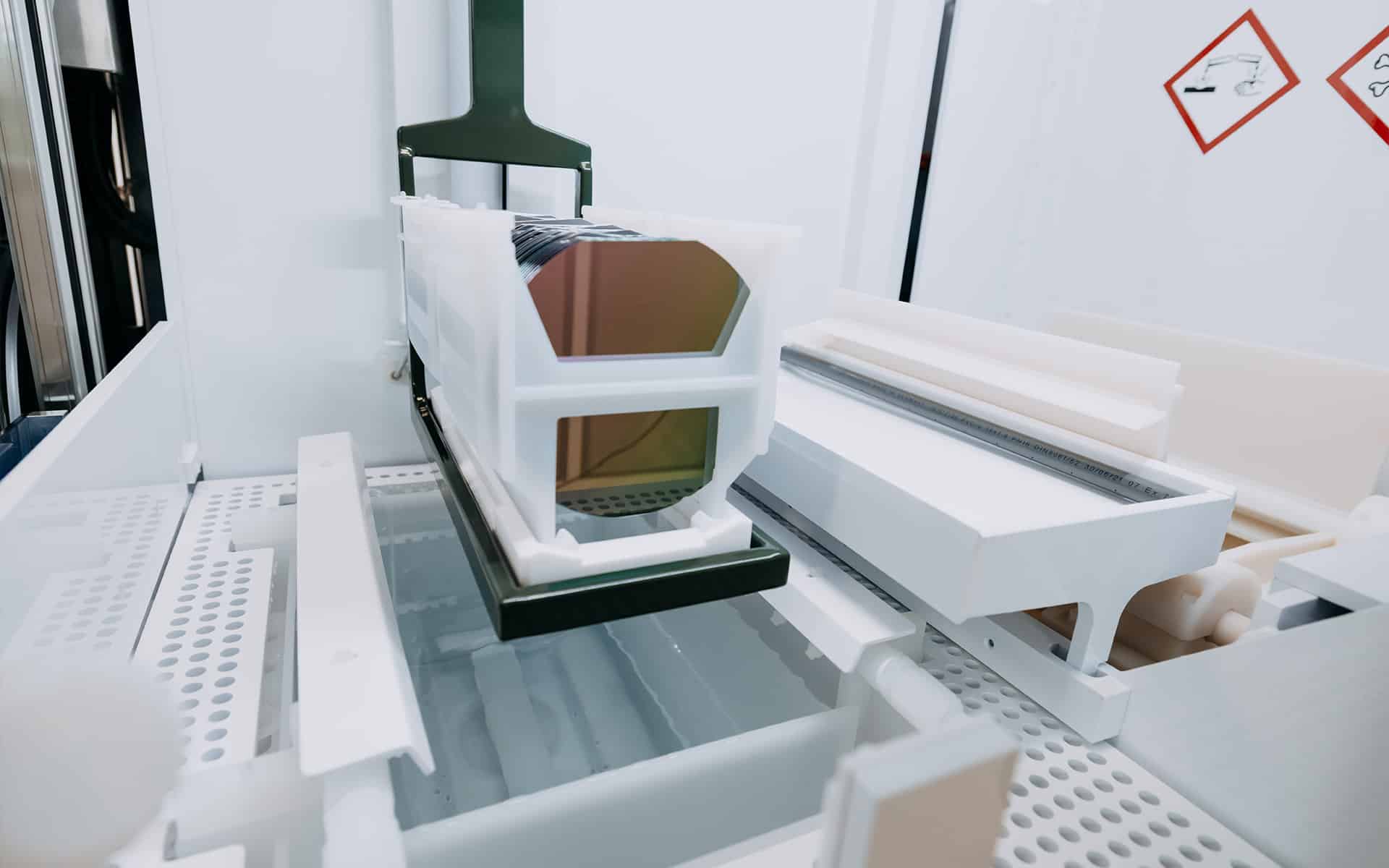

Semi-automatic wet bench with two process chambers and a dry-in/dry-out functionality

TwinStep

AP&S PRODUCTS

Etching, cleaning and drying in an unbeatably compact footprint

This plant convinces by its very compact design. Functionality with optimum process control takes place here in two process chambers. The dry-in/dry-out function is suitable for a wide range of applications. Reliability and simplicity meet state-of-the-art wet process technology, making the TwinStep an optimal entry-level batch model as well as the first-choice supplementary tool when the available clean room is tight.

Main Benefits

- Smart, modular design - access is only required from two sides (front and back)

- Convenient handling and loading: 1 rinse tank via the front and 1 chemical tank on the rear side

- Superior reliability and process repeatability at 97 % uptime

- Robust wafer handling system for highest process reliability

Processes

- Different etching and cleaning processes

Substrates

- Substrates

Wafers, MEMS, optoelectronics, photomasks, glass - Wafer material

Si, SiC, GaN, GaAs, sapphire, glass - Wafer sizes

up to 12″

Technical Features

- Optimized footprint (LxWxH): 900 x 1625 x 2000 mm

- Complies with FM 4910, SEMI S2 and S8, SECS / GEM, in CE

- Process control through the latest software technology:

Sensor software interface, suitable for in-house tracking system, extensive process documentation (consumption, media, temperature, cleaning cycles, end of run, login), individual recipes