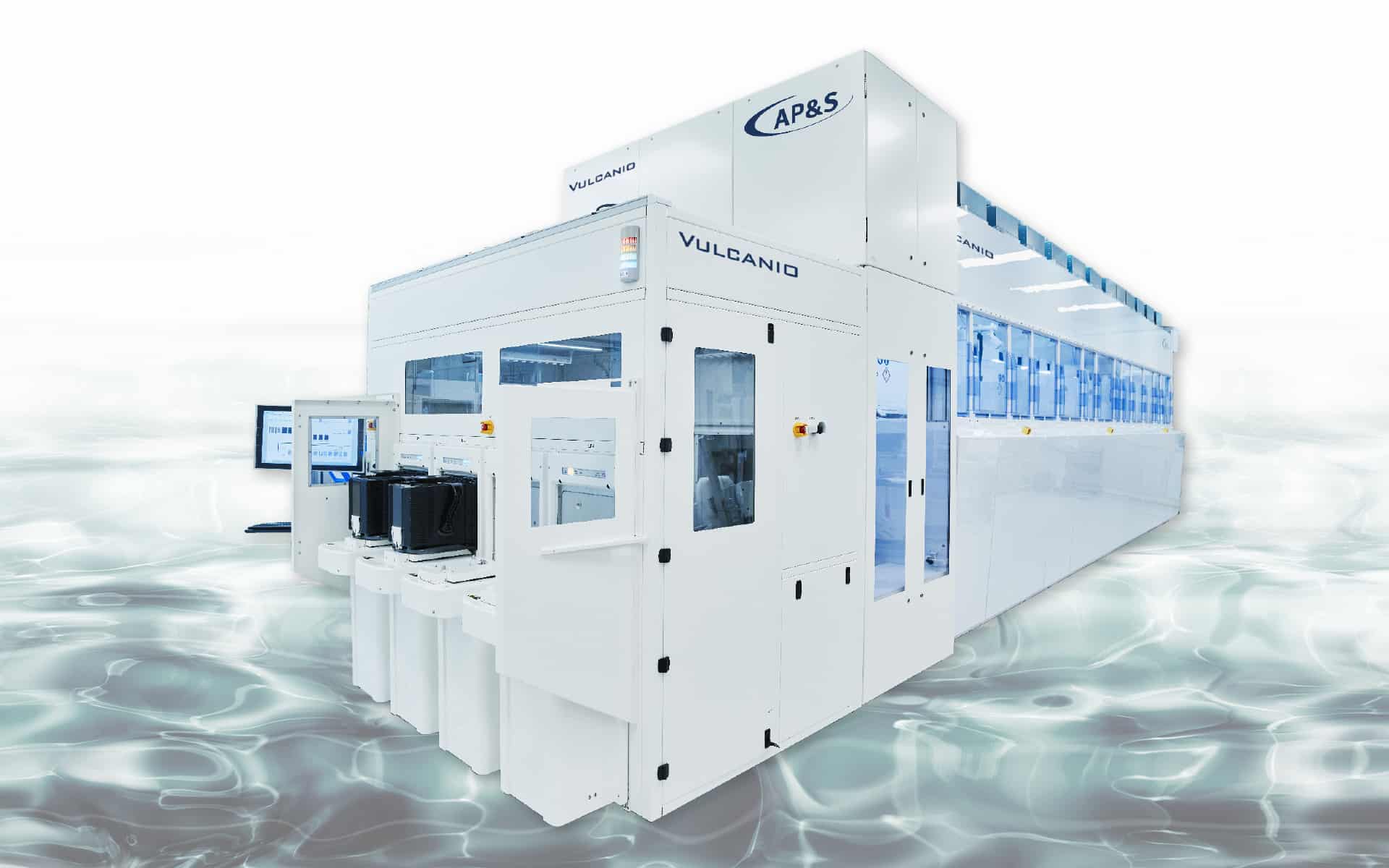

Vulcanio

The high-throughput electroless wet bench for under-bump metallization (UBM) with nickel, palladium and gold.

AP&S PRODUCTS

Advanced UBM

Vulcanio is our response to the increasing importance of flip-chip bonding and the further miniaturization of components.

Vulcanio is a high throughput wet bench for wafers up to 300 mm. The batch tool is specifically designed for under-bump deposition with electroless plating technology on Al- and Cu-based substrates for metallization with nickel, palladium and gold. The e-less system has been successfully used for mass production by leading semiconductor manufacturers since 2009. Since then, the Vulcanio has been continuously further developed and optimized in close coordination with customers.

Main Benefits

- Specially developed and optimized for UBM (Under Bumping Metallization) of aluminum or copper pads (nickel, palladium, immersion gold)

- Unique software and hardware features ensure exceptional deposition uniformity, bath longevity and an unbeatable operating cost ratio.

- Process-specific analyzers and optimized metering ensure comprehensive process control and maximum reliability.

Read our article: Advanced under-bump metallization (UBM) with the AP&S e-less system Vulcanio - 7 unbeatable facts that are convincing

Processes

- Currentless UBM for Al and Cu pads (Ni, Pd, Au)

Substrates

- Substrates

Wafer up to 300mm - Wafer material

Si, SiC, GaN - Wafer sizes

up to 6″, 8″ and 12″

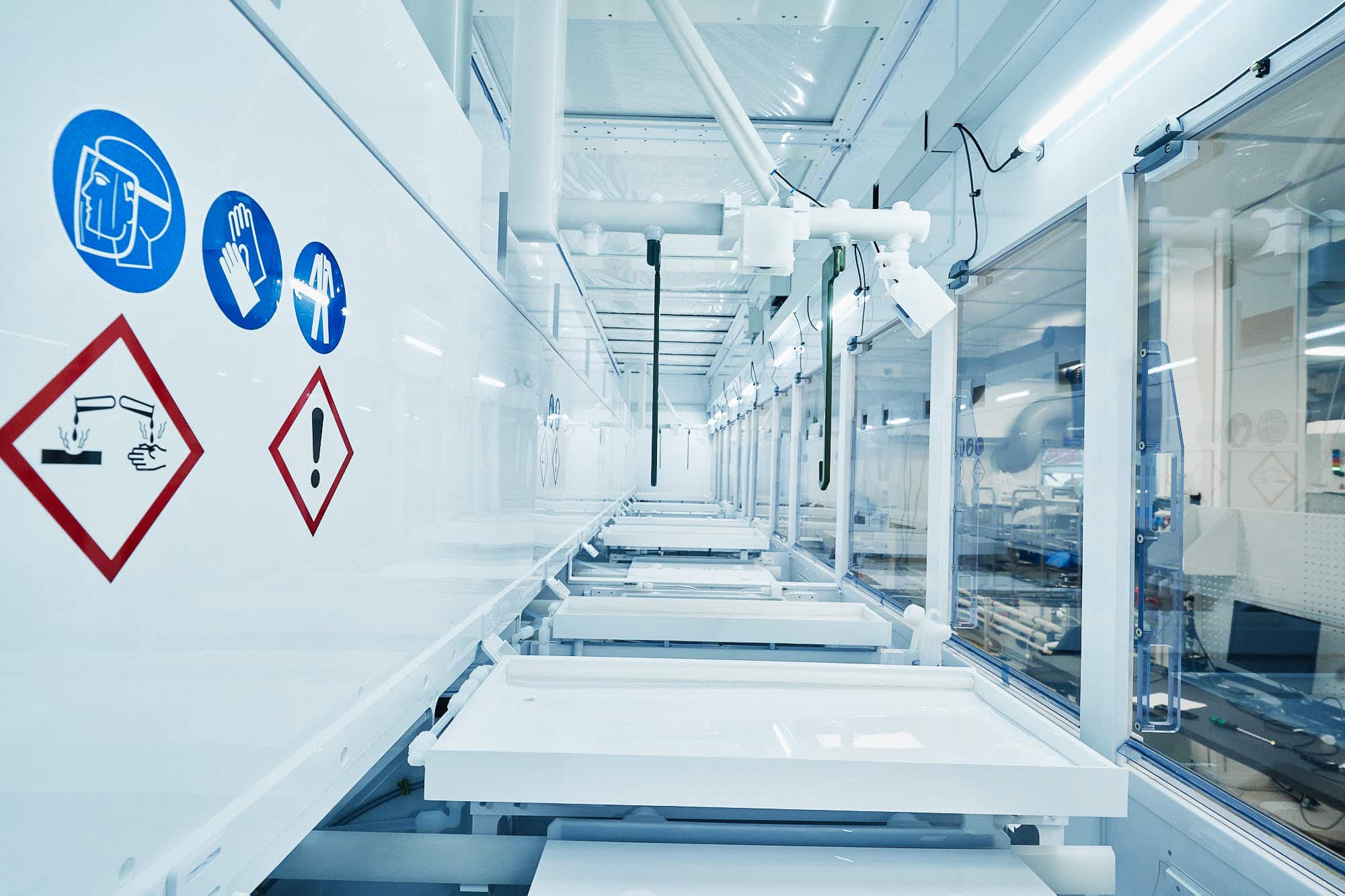

Technical Features

- Fully automated wafer handling

- FOUP system suitable (300 mm)

- SMIF system suitable (150, 200 mm)

- Processes 25 or 50 wafer batches from 6" to 12" wafers

- Works with high and low profile cassettes

- Dry-In / Dry-Out processing

- Complies with: FM 4910, SEMI S2 and S8, SECS, GEM, CE

- Process control through the latest software technology:

Sensor software interface, suitable for in-house tracking system, extensive process documentation (consumption, media, temperature, cleaning cycles, end of run, login), individual recipes