MultiStep

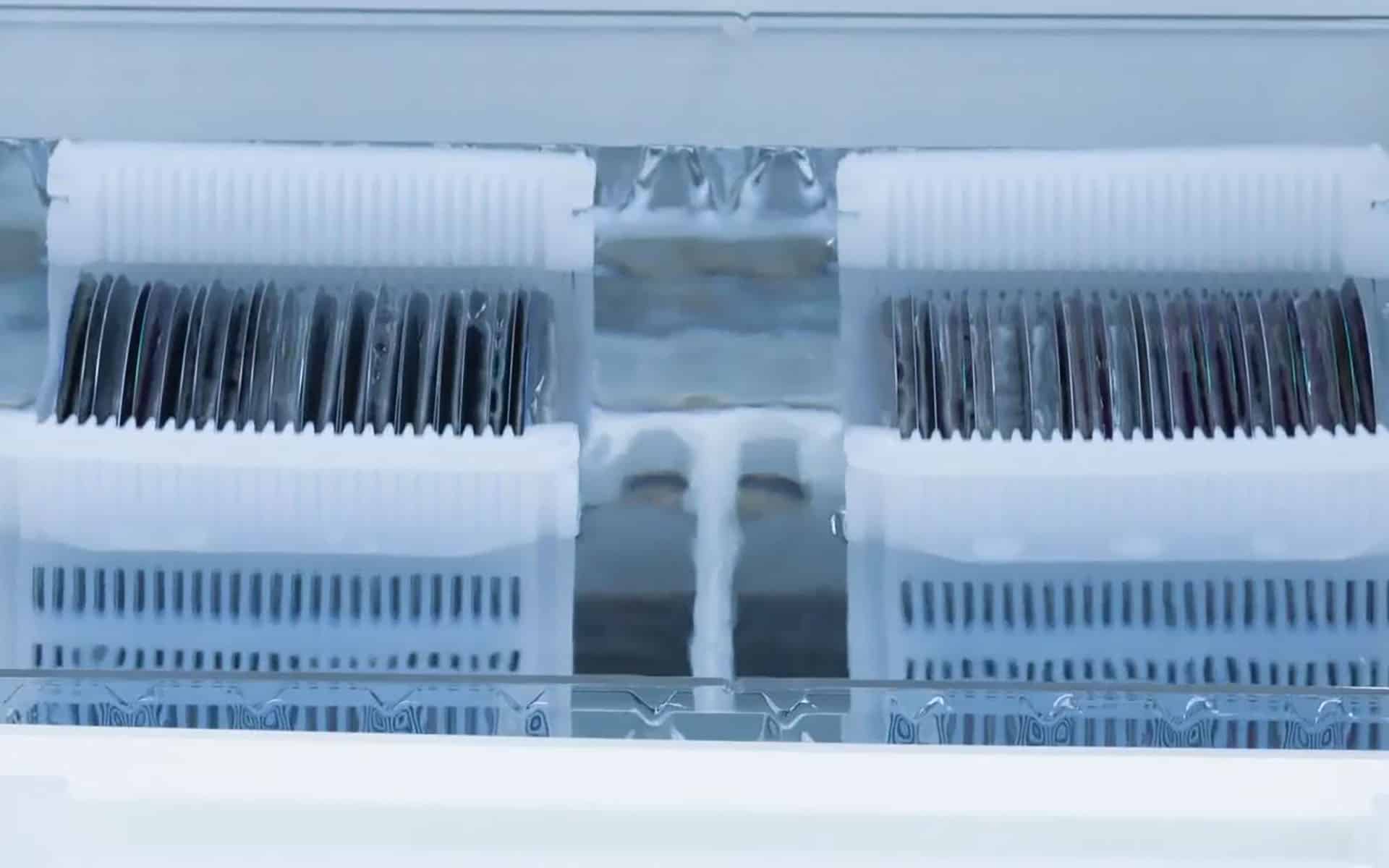

Semi-automatic wet bench with a compact footprint and a wide range of configuration options

MultiStep

AP&S PRODUCTS

Modular

A compact wet process plant that can be expanded at any time thanks to its modular design, thus offering AP&S customers a high degree of flexibility

Main Benefits

- Smart, modular design for convenient and cost-effective installation and maintenance as well as for high flexibility for upgrades

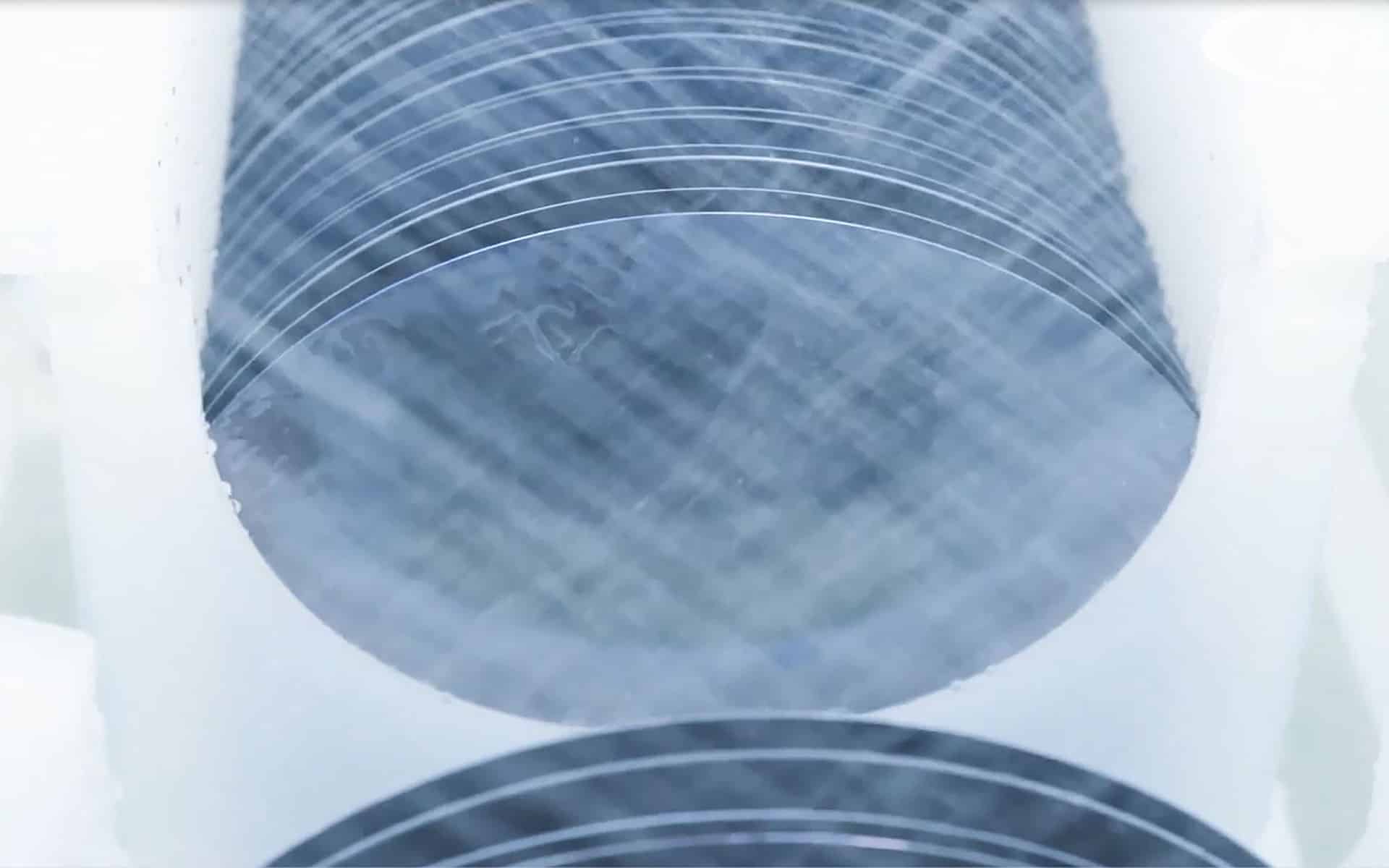

- Different wafer sizes and thicknesses can be processed, no adjustments/modifications to the system are required for this purpose.

- Highest reliability with a plant operating time of ≥ 97%

Processes

- Different wet cleaning proceses

- RCA

- Pre-diffusion

- Pre-metal

- Different etching processes, including oxide, nitride, polycrystalline, metals and silicides

Substrates

- Substrates

Wafers, MEMS, optoelectronics, photomasks, glass - Wafer material

Si, SiC, GaN, GaAs, Sapphire, Glass - Wafer sizes

up to 8″

Technical Features

- Optimized plant footprint

- The plant configuration can be adapted cost-effectively to future product / process changes and customer requirements

- Processes 2 x 25 wafer stacks with 4 to 6" or 25 x 8" substrates

- Complies with: FM 4910, SEMI S2 and S8, SECS, GEM, CE

- Process control through the latest software technology:

Sensor software interface, suitable for in-house tracking system, extensive process documentation (consumption, media, temperature, cleaning cycles, end of run, login), individual recipes