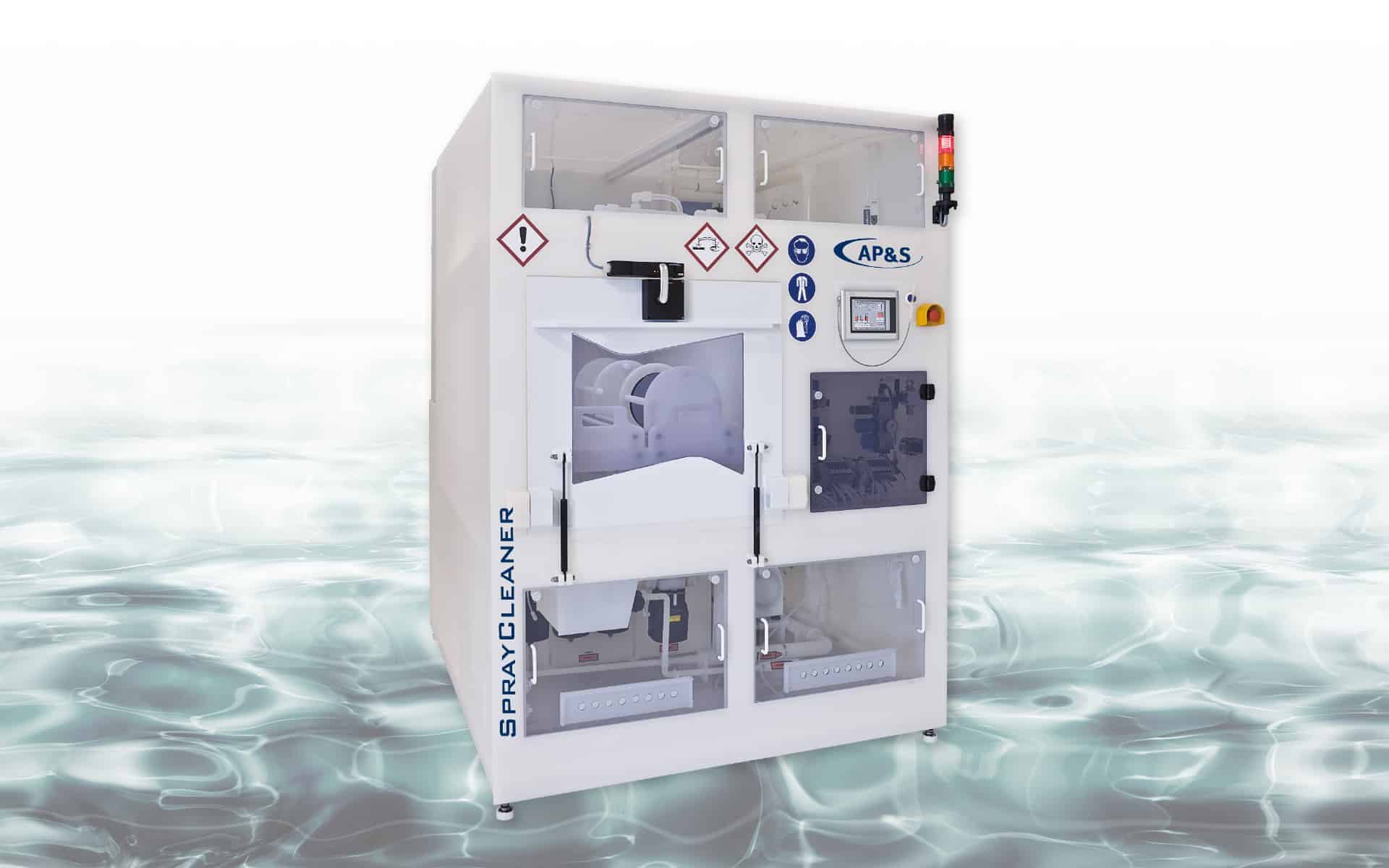

SprayCleaner

The SprayCleaner is designed for etching and cleaning PECVD and diffusion boats such as graphite boats, quartz parts and silicon carbide boats.

SprayCleaner

AP&S PRODUCTS

Cleaning and etching of PECVD and diffusion boats.

The AP&S SprayCleaner is the perfect tool for etching or cleaning PECVD and diffusion boats. The innovative spray cleaning technology achieves optimized process times with lower chemical consumption.

Main Benefits

This system uses an innovative spray cleaning technique that achieves optimized process time while requiring less chemical consumption compared to an immersion process.

Processes

Etching and cleaning

Substrates

PECVD and diffusion boats

Technical Features

- Optimization of CoO due to very small footprint and lower DI water consumption, half that of an immersion process.

- Minimized cleaning costs per boat due to low chemical consumption which is ten times lower than that of an immersion process

- Maximum safety for the operator as the system only operates when the chamber is closed. Loading and unloading only takes place after the process chamber has been completely flushed. Furthermore, a fail-safe door interlock is installed.

- Highest process reliability through overfill protection and exhaust gas monitoring

- High and fast availability as well as low maintenance due to modular design and durable components